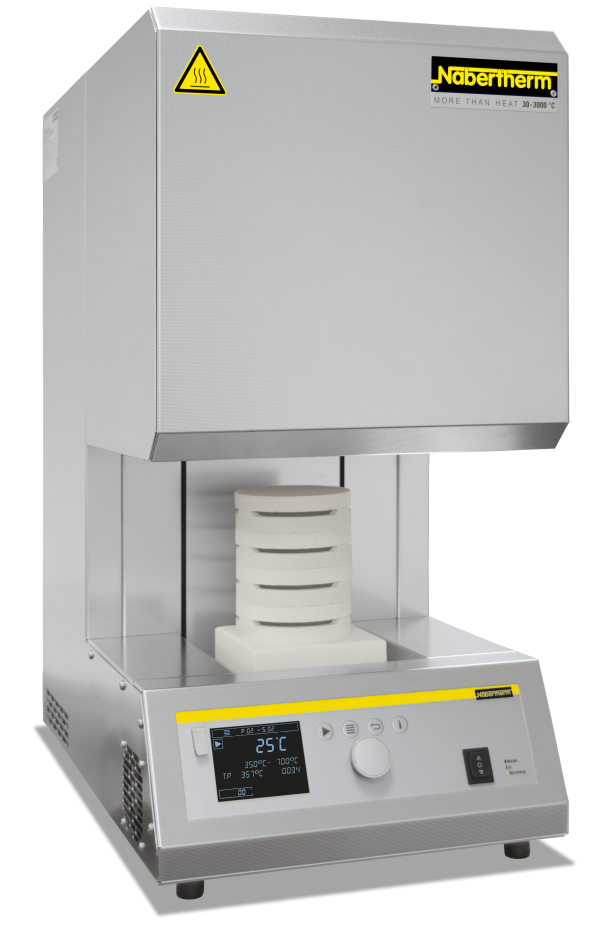

The motorized lifting table significantly simplifies the charging of the high-temperature furnaces LHT ../.. LB (Speed). The heating all around the cylindrical furnace chamber provides for an opitimal temperature uniformity. For the tabletop models LHT 01/17 LB Speed and LHT 02/17 LB Speed the charge can be placed in charge saggars made of technical ceramics. Up to three charge saggars can be stacked on top of each other resulting in a high productivity.

Standard Equipment

- Tmax 1650 °C, 1700 °C (LHT 16/17 LB)

- High-quality heating elements made of molybdenum disilicide offer very good protection against chemical interaction between charge and heating elements

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Excellent temperature uniformity thanks to three (LHT 02/17 LB Speed) or four-sided (LHT 01/17 LB Speed) heating of the furnace chamber

- Furnace chamber with a volume of 1, 2 or 16 liters, table with large floor space

- Precise, motorized toothed belt drive of the table with button operation

- Exhaust air vent in the roof

- Type S thermocouple

- Controller P480 (50 programs with each 40 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Process Control and Documentation

As one of the world’s largest furnace manufacturers, Nabertherm has many years of experience in the design and manufacture of standardized and customer-specific control systems. All controls are characterized by a very high level of operating convenience and even the basic version has extensive basic functions. Depending on the requirements, the functions can be expanded and adapted to your needs. Professional software solutions for single or multiple furnace management as well as process and batch documentation based on our Nabertherm controllers complete the range.

Also for compliance with industry-specific standards that define process control and documentation, such as for example, the AMS 2750 F for aviation, the CQI-9 in the automotive industry or the FDA in the pharmaceutical industry we offer standardized solutions.

Additional Equipment

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the oven and load

- Stackable saggars for loading in up to two or three levels, depending on model

- Adjustable air inlet through the floor

- Process control and documentation via VCD software package for monitoring, documentation and control